Automatic Filling Machine for 20L pail

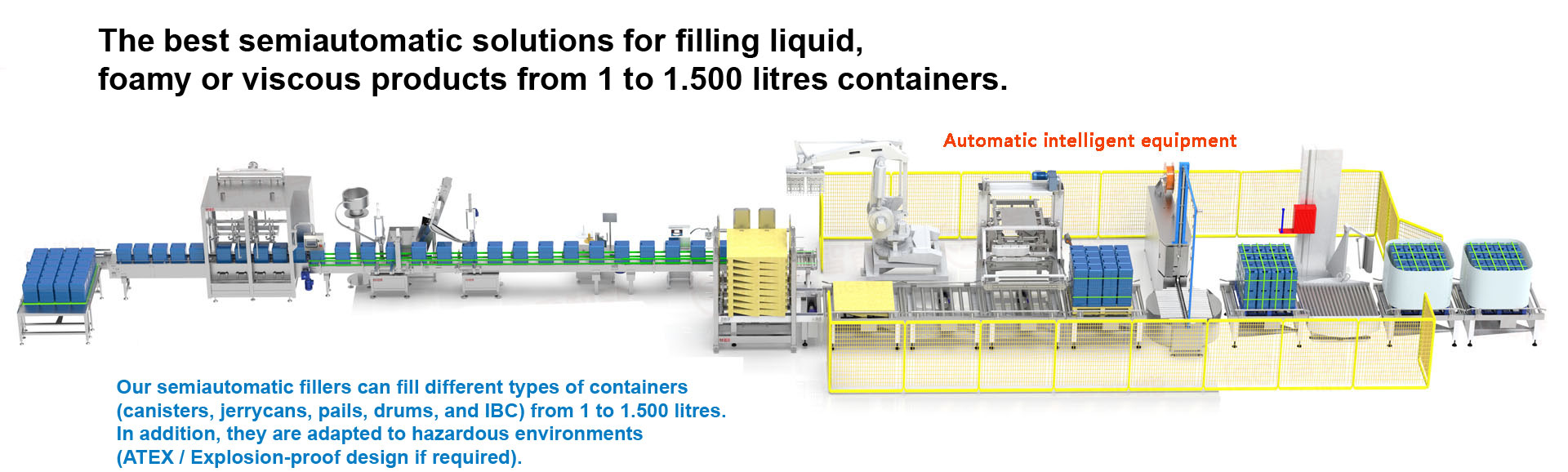

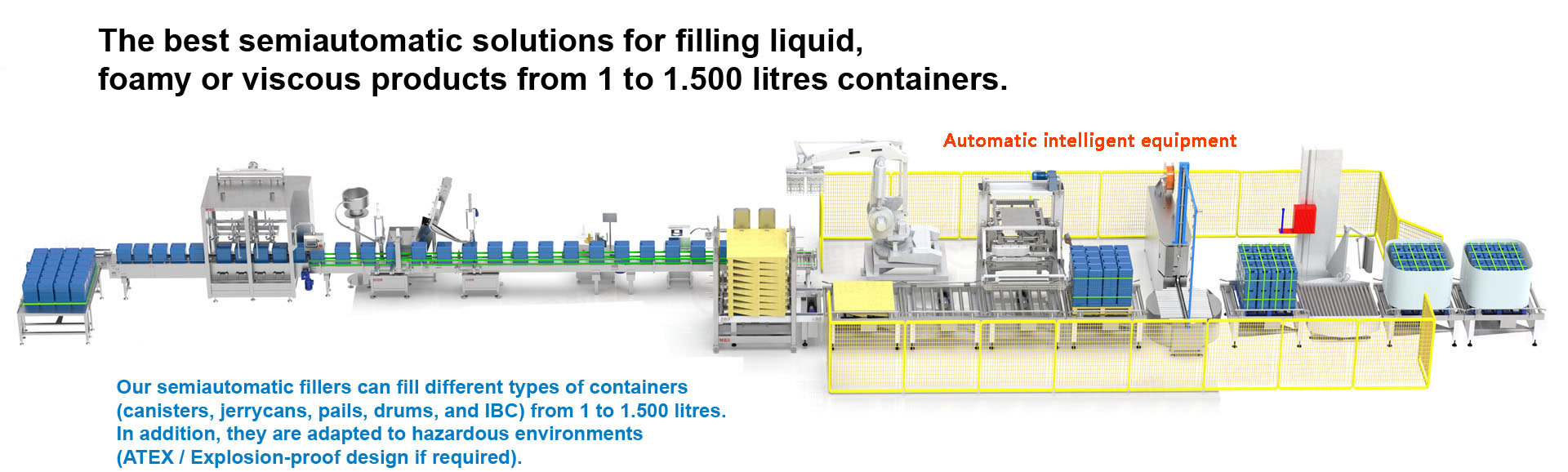

Automatic Filling Machine for 20L Pails is a specialized piece of equipment designed to accurately and efficiently fill large containers, such as 20-liter pails, with liquids or semi-liquids. These machines are commonly used in industries like chemicals, food and beverage, pharmaceuticals, and cosmetics, where precise filling and high throughput are essential.

High Accuracy:

Equipped with advanced flow meters, load cells, or piston filling systems to ensure precise filling volumes, minimizing product waste.

High Speed:

Versatility:

Can handle a wide range of liquids, including viscous, corrosive, or foamy substances, depending on the configuration.

Automation:

Durability:

Safety Features:

Customization:

Can be tailored to specific product requirements, such as filling heads, nozzle types, and sealing options.

Integration:

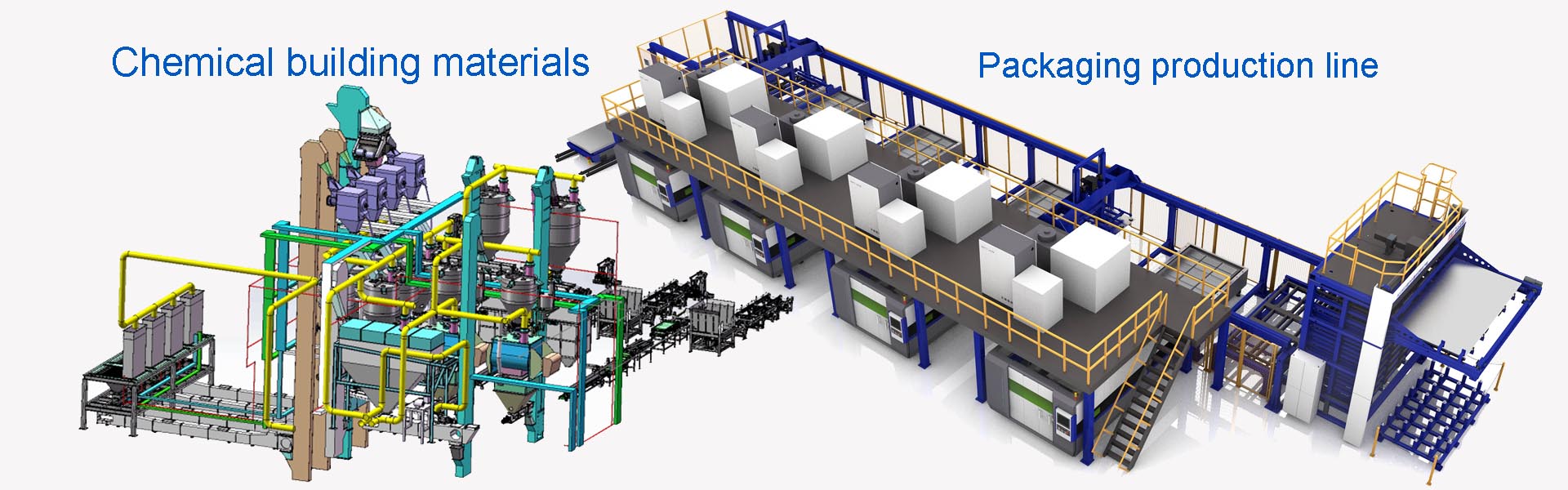

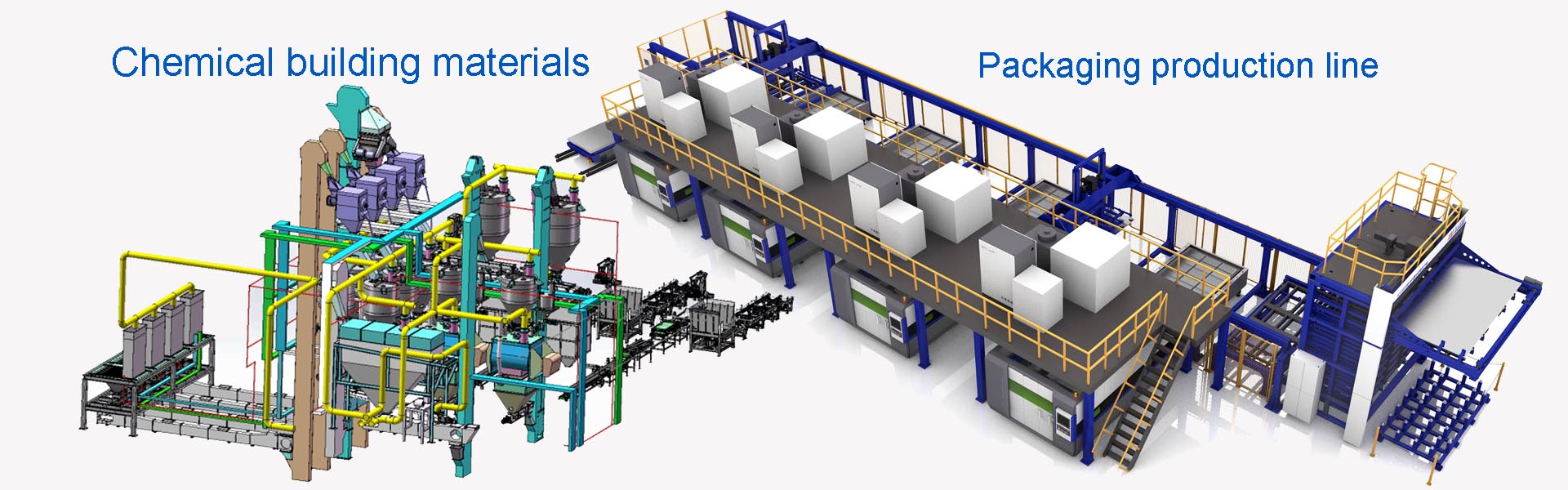

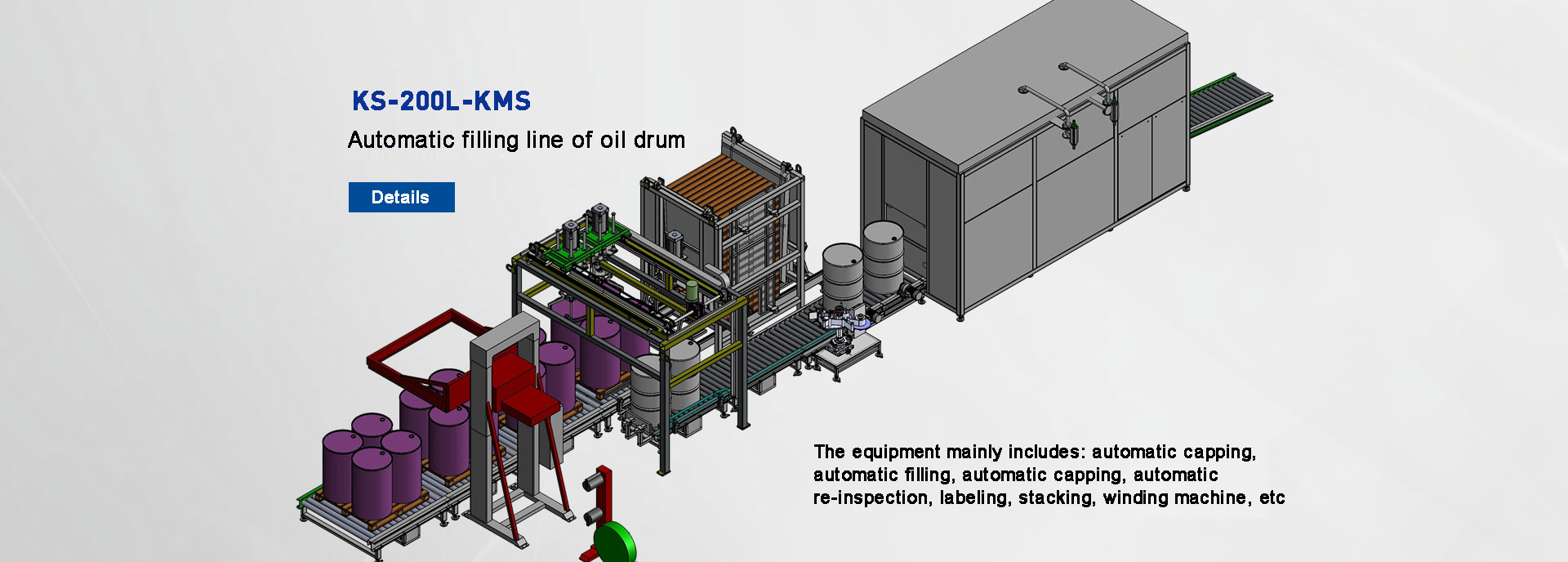

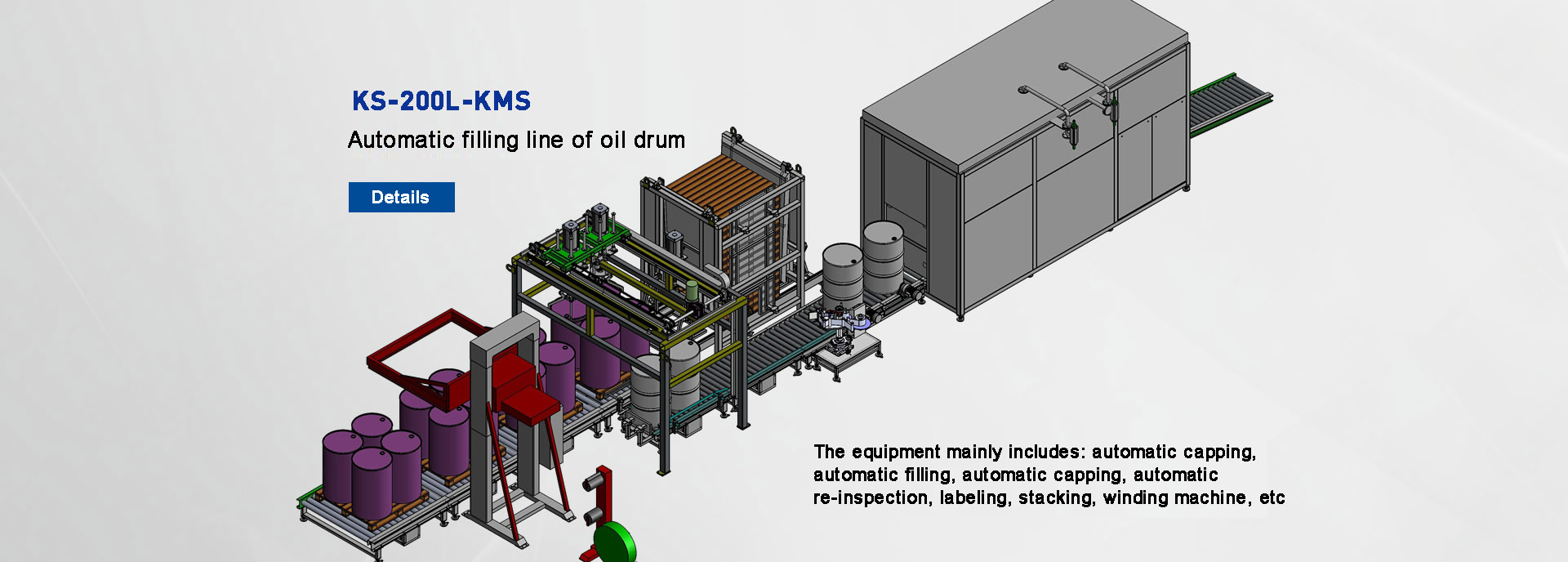

Designed to integrate seamlessly with other production line equipment, such as capping machines, labeling systems, and conveyors.

Components of a 20L Pail Filling Machine:

Filling Nozzles:

Designed to prevent drips and spills, with options for different nozzle types (e.g., sanitary, anti-foam).

Conveyor System:

Pail Positioning:

Control Panel:

Pump System:

Drip Trays and Splash Guards:

Applications:

Chemicals: Filling detergents, solvents, or industrial cleaners.

Food and Beverage: Oils, sauces, syrups, or beverages.

Pharmaceuticals: Liquid medications or sanitizers.

Cosmetics: Lotions, creams, or shampoos.

Benefits:

Increased Productivity: Reduces manual labor and speeds up the filling process.

Consistency: Ensures uniform fill levels across all pails.

Cost Savings: Minimizes product loss and reduces operational costs.

Compliance: Meets industry standards for hygiene and safety.

Considerations When Choosing a Machine:

Product Characteristics:

Production Volume:

Space Constraints:

Budget:

After-Sales Support:

If you’re looking for a specific model or supplier, let me know, and I can help guide you further!