Solvent filling machine

Solvent filling machine

- Brand::

- Model::

Solvent filling machine

Solvent filling machine

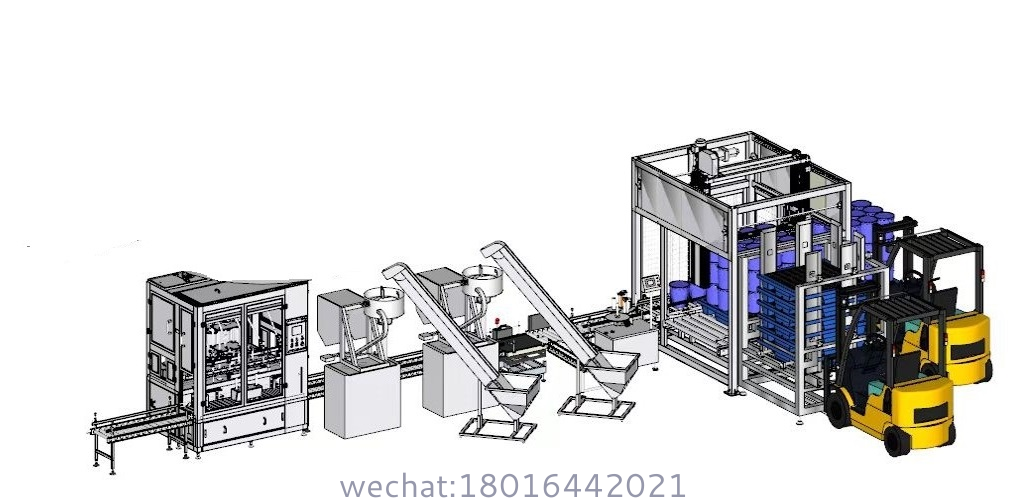

A solvent filling machine is a specialized industrial device designed to accurately and safely fill solvents into containers such as bottles, cans, drums, or intermediate bulk containers (IBCs). Solvents, which are often flammable, volatile, or hazardous, require careful handling to ensure safety and precision during the filling process. These machines are engineered to meet strict safety standards while maintaining high efficiency and accuracy.

High Precision:

Ensures accurate filling volumes to meet product specifications and reduce waste.

Safety and Containment:

Designed to prevent leaks, spills, and exposure to hazardous solvents.

Often includes features like explosion-proof components, sealed filling systems, and fume extraction.

Versatility:

Capable of handling various types of solvents, including flammable, corrosive, and volatile liquids.

Durability:

Constructed from materials resistant to chemical corrosion, such as stainless steel or specialized plastics.

Automation:

Fully or semi-automated systems to increase production speed and reduce manual labor.

Easy Cleaning and Maintenance:

Designed for quick cleaning to prevent cross-contamination between different solvent types.

Customizable:

Can be tailored to specific production needs, such as filling speed, container type, and solvent properties.

Piston Filling Machines:

Ideal for high-viscosity solvents or those requiring precise measurements.

Uses a piston mechanism to dispense the solvent.

Gravity Filling Machines:

Suitable for low-viscosity solvents.

Relies on gravity to fill containers.

Pump Filling Machines:

Used for medium to high-viscosity solvents.

Employs pumps to transfer the solvent into containers.

Overflow Filling Machines:

Designed for filling containers to a consistent level, regardless of minor variations in container size.

Ideal for solvents used in applications requiring precise fill levels.

Net Weight Filling Machines:

Uses a weighing system to fill solvents by weight, ensuring high accuracy.

Suitable for solvents sold by weight rather than volume.

Rotary Filling Machines:

High-speed machines with multiple filling heads for large-scale production.

Ideal for filling containers simultaneously.

Semi-Automatic vs. Automatic Machines:

Semi-Automatic: Requires some manual intervention, such as placing and removing containers.

Automatic: Fully automated, handling container placement, filling, and sealing.

Filling industrial solvents like acetone, toluene, and methanol.

Packaging cleaning agents and degreasers.

Dispensing chemical solvents for pharmaceuticals, cosmetics, and laboratories.

Filling flammable solvents with explosion-proof safety features.

Improved Efficiency:

Faster filling speeds and reduced downtime.

Consistency:

Uniform fill levels across all containers.

Cost Savings:

Reduced material waste and labor costs.

Safety:

Minimized human exposure to hazardous solvents.

Compliance:

Meets regulatory standards for handling and packaging hazardous liquids.

Scalability:

Suitable for small, medium, or large-scale production.

Solvent Properties:

Consider viscosity, flammability, and corrosiveness.

Production Volume:

Match the machine's capacity to your production needs.

Container Type and Size:

Ensure compatibility with your packaging (e.g., bottles, drums, IBCs).

Automation Level:

Decide between semi-automatic or fully automatic systems based on your budget and production scale.

Safety Features:

Look for explosion-proof components, sealed systems, and fume extraction.

Ease of Cleaning:

Important for switching between different solvent types.

Budget:

Balance initial cost with long-term benefits and ROI.

Accutek Packaging Equipment: Offers versatile filling solutions for hazardous and non-hazardous liquids.

Krones: Known for high-speed liquid filling machines.

Fillon Technologies: Specializes in liquid filling machines for chemicals.

APACKS: Provides customizable filling systems for solvents and other liquids.

If you need help selecting a solvent filling machine or have specific requirements, feel free to provide more details!